Introduction to Rotary Switches, Encoders and Coded Switches

In this month’s blog we are going to look at what Rotary Switch, Rotary Encoder and Coded Switches are, how they work, their benefits and what the difference is between each one.

1st April 2021

In this month’s blog we are going to look at what Rotary Switch, Rotary Encoder and Coded Switches are, how they work, their benefits and what the difference is between each one.

A Rotary Switch is operated by the rotation of an actuator, they are often chosen when 2 or more positions are needed to select different electrical circuits within a device. Rotary Switches can stop in several positions to control multiple circuits with a single switch. They are normally available with a choice of shorting (make before break) or non-shorting (break before make) contacts.

The advantages of Rotary Switches are they can control numerous circuits without the need for multiple switches as they can be designed with numerous contact points. Rotary switches are commonly used in applications including CB radios, industrial controls, electronic instruments and even aircraft, although they are less common than they used to be. Rotary Switches can also be designed with a detent mechanism so they “click” and hold from one active position to another rather than stalling in an intermediate position.

Live Electronics works with Dailywell, Idec, Lorlin and Elma, who between them manufacture a vast range of Rotary Switches. Elma also make precision versions of Rotary Switches. Dailywell manufacture the RT2 Series that are designed as single pole switches with between 2 and 8 positions with off in the extreme anti-clockwise position and between 45° to 360° travel depending on the number of positions. They have a mechanical life of 10,000 cycles. The RT2 series is perfect for applications such as Telecommunication Equipment, Computer Peripherals, Networking Systems and Audio-Video Equipment.

Elma specialise in manufacturing precision Rotaries, including the highly reliable and rugged MR50 Rotary Switch which has a miniature body of just ½ an inch in diameter and is sealed to IP68. The switch is available in 10, 12 and 16 positions. It has a minimum mechanical life of 20,000 cycles. The internal contacts are also gold plated to ensure reliable switching at low voltages. Due to its robust nature and operating temperatures of -45°C to +85°C the MR50 is perfect for demanding applications including Two Way Radios, Medical and Testing Equipment, Military Targeting Devices and Night Vision Devices.

Rotary Encoders are devices that convert the rotational movement of the shaft into an analogue or digital signal. This is done by converting an input voltage into a different output voltage (analogue) or a digital signal depending on the position of the shaft. It provides information on position, speed, count or direction. They Key benefit of using a Rotary Encoder Switch is that it can rotate in the same direction indefinitely. Due to their robustness and fine digital control; they are used in many applications including robotics, CNC machines and printers. Rotary Encoder Switches measure rotary movements and displacement and can either be absolute or incremental which we will explain below.

Within an Absolute Encoder Switch, the position is retained regardless of whether the encoder is powered or not, even if a movement is made without power to the encoder, the encoder still knows the true position. These can either be single turn or multi-turn, whereby the requirement is to know not only the position over one turn of the shaft but how many turns have been made in total. Multi-turn encoders are suited to applications where complex or lengthy positioning measurements are involved. Single-turn encoders are more suited to short travel applications where position measurement is required within a single turn of the encoder.

There are several advantages to the Absolute Encoder and these are as follows; their true position is not lost if there is a loss of power, continuous reading of a position is not required, and they provide high resolution up to 16 bit single and 44-bit multi-turn.

An Incremental Encoder Switch works by transforming the angular position of the shaft into digital or pulse signals by means of an optical disk. A certain number of pulses are generated per revolution and each pulse is an increment corresponding to the defined resolution. An Incremental Encoder can measure the change in position but not the absolute position.

Every time an Incremental Encoder is switched on the pulse is counted from zero, this means that the position is not stored and a ‘reset or reference’ position must be obtained before the encoder begins counting again. This is the main difference between an absolute and an incremental encoder.

The advantages of Incremental Encoder Switches are, they are more cost effective and less complex compared to an Absolute Encoder Switch and they can determine speed and direction.

At Live Electronics we work with Elma who manufacture the E18 series which is a mechanical Incremental Encoder designed to offer high performance characteristics. It has a mechanical life of up to 150,000 revolutions, the E18 is a small and very robust encoder. It has a shaft sealing of IP68 and offers a large variety of shaft dimensions and shapes. It is available with or without a push button function and has various shaft types that include brass and stainless steel. The E18 series is perfect for applications such as White Goods Equipment, Home Automation, Two Way Radio Equipment, Industrial Controls and Audio and Entertainment Equipment.

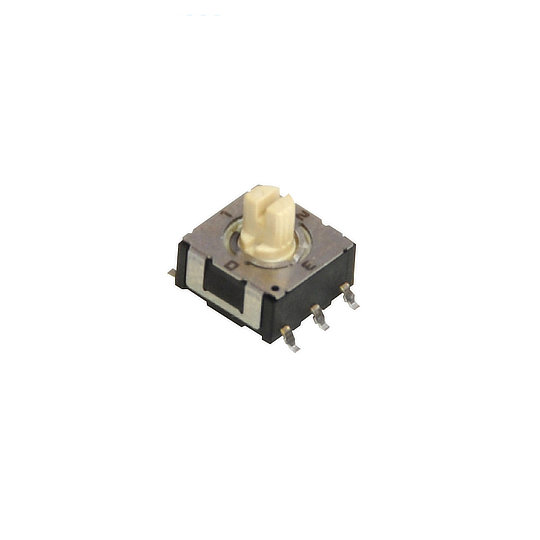

A Rotary Coded Switch is used to select one of several options. This device is like a rotary switch, except the outputs are binary encoded to reduce the number of terminations required. Rotary Coded Switches are activated by a rotating shaft and have several positions. They are mounted on printed circuit boards (PCBs) in order to control their output. Some Rotary Coded Switches are actuated with a screwdriver, others include thumbwheels or push wheels that are turned manually. They can be designed either to rotate continuously through 360 degrees, or to stop at pre-set positions as they turn.

Rotary Coded Switches have many advantages which include their mechanical life, number of positions, they can rotate 360 degrees or stop at pre-set positions as they rotate, and they can be used in applications including Two Way Radio Devices, Target Aiming Devices, Aircraft Transponders, Medical Equipment and Industrial Automation Equipment.

Dailywell and Elma manufacture Rotary Coded Switches. Dailywell manufactures the single pole RSC series Rotary Coded Switch with 4, 10, or 16 positions through 360 degrees. They are available with real or complementary code and have a mechanical life of 10,000 cycles. The RSC series are ideal for applications such as Telecommunication Equipment, Computer Peripherals, Networking Systems and Audio-Video Equipment.

While all are activated by a rotating shaft the differences are that a Rotary Switch selects different electrical circuits within a device. An Encoder Switch converts the rotational movement of the shaft into an analogue or digital signal, while a Coded Switch uses binary coded outputs to reduce the number of pins required.

The advantage of using a Rotary Switch over a Rotary Encoder Switch is having several positions to control many different circuits with a single switch. They are used in many applications including CB radios, industrial controls, electronic instruments and aircraft. The advantages Rotary Encoder Switches have over Rotary Switches include being able to convert the rotational movement of the shaft into an analogue or digital signal and it provides information on position, speed, count or direction.

The advantages of using a Rotary Switch over a Rotary Coded Switch include being able to control many different circuits with a single switch. The advantages Rotary Coded Switches have over Rotary Switches include the reduction in the number of pins due to the output being binary encoded and they are available with real or complementary code.

The advantages Rotary Encoder Switches have over Rotary Coded Switches include converting the rotational movement of the shaft into an analogue or digital signal and they provide information on position, speed, count or direction. Rotary Coded Switches advantage over Rotary Encoder Switches is having the option for several distinct positions.

Binary-Coded Decimal

Binary-Coded Decimal is a class of decimal numbers where each digit is represented by a fixed number of bits, usually four or eight. Sometimes, special bit patterns are used for a sign or other indications (e.g., error or overflow).

Hexadecimal Code

The Hexadecimal, or Hex, numbering system is commonly used to reduce large strings of binary numbers into a set of four digits for us to easily understand. Hexadecimal numbering system uses 16 different digits, a combination of 0-9 & A-F and are a popular choice for representing long binary values because their format is compact.

Gray Code

Gray Code or Reflected Binary Code (RBC) is ordering of the binary numeral system such that two values differ in only one bit for example the representation of the decimal value “1” in binary would normally be “001” and “2” would be “010”. In Gray code, these values are represented as “001” and “011”. That way, incrementing a value from 1 to 2 requires only one bit to change, instead of two.

Gray Code is widely used to prevent false output from electromechanical switches and to facilitate error correction in digital communications such as digital terrestrial television and some cable TV systems.

Rotary Switches are operated by rotation and can stop in several positions to control many different circuits with a single switch.

Most Rotary Switches are PCB mount and installation will all depend on the boards design. If you are manually installing a Rotary Switch you will need to prepare your wires and connect the supply wire to the supply (common) terminal, usually found in the centre of the switch terminations, and connect the remaining wires to the different contacts in relation to the circuit they are switching.

A Rotary Switch is operated by rotation, they are often chosen when 2 or more positions are needed to select different electrical circuits within a device.

A Rotary Switch is used for many applications including CB radios, industrial controls, electronic instruments and even aircraft.

A Rotary Coded Switch is used to select one of several options. This device is like a rotary switch, except the outputs are binary encoded to save on pin requirements.

Rotary Encoders are devices that convert the rotational movement of the shaft into an analogue or digital signal. They provide information on position, speed, count or direction.

A Rotary Encoder Switch produces either analogue or digital signal, according to the rotational movement.

A Rotary Encoder Switch detects rotation angle or linear displacement. Encoders Switches are used in devices that need to operate in high speed and with high accuracy.

Contact our sales team today to discuss your switch requirements! Contact Us

Compact & Powerful Automation Solution: IDEC’s FT2J 7-inch PLC+HMI Now Available from Live Electronics!

Posted on 11th July 2024 by Marcia Pearson

Exploring the Power and Potential of IoT: Understanding MQTT Protocol

Posted on 30th May 2024 by Marcia Pearson

Beehive Management with Weipu’s SP Series Connectors

Posted on 24th May 2024 by Marcia Pearson