IDEC’s Solution: ‘Safe Break Action’

IDEC, a leading manufacturer of industrial automation and control solutions, addresses this challenge with its E-stop ‘Safe Break Action’ feature. This technology ensures fail-safe operation even in the rare event of contact block failure.

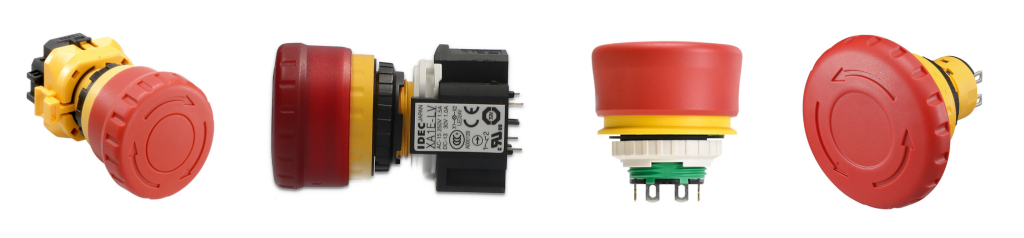

IDEC’s E-stops are designed with a positive opening mechanism, also known as ‘Safe Break Action’. This means that the E-stop contacts have the spring pressure in the opposite direction meaning it will always fail in the safe position and cannot be defeated by welding or sticking contacts, thus ensuring reliable and consistent operation.

These E-Stops are also available with 1 to 4NC contacts, depending on the series, and can include 1NO monitor contact to ensure no faults are missed. These additional contact options also mean that these E-stop switches can be used in Level 4 safety category applications.

To conclude, IDEC’s E-stop ‘Safe Break Action’ feature represents a significant advancement in industrial safety technology. By combining fail-safe operation with ‘Safe Break Action’, IDEC provides a reliable and robust solution to enhance safety in industrial environments. As businesses strive to create safer workplaces and comply with regulatory standard, investing in advance safety technologies like IDEC’s E-stop switches in a proactive step towards achieving these goals.