Shells, Inserts, Contacts And Backshells

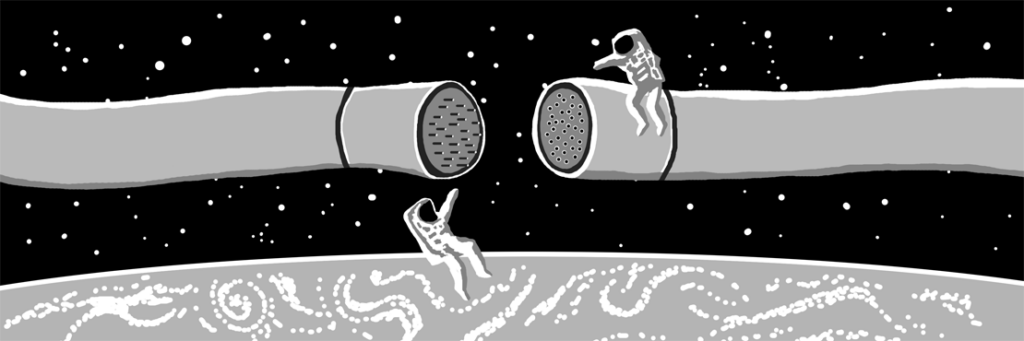

Circular connectors as judged by their name consist of two circular parts, a multi-pin male plug and a multi-socket female receptacle. In the male plug a circular shell made from plastic or metal encases an insulating insert which in turn orientates electrical contacts or pins. The female receptacle contains the corresponding sockets that the pins mate or connect with. The shell diameters range in size from nanominiature circular shells a few millimetres across to those 50 mm in diameter or more. Larger shell sizes are generally used to house larger contacts used for power or more contacts whereas smaller shells are designed to house the smaller contacts needed for sensors.

The cylindrical housing and circular contact interface geometries allow for easier engagement and disengagement, tight environmental sealing, and rugged mechanical performance. The male plug of the connector containing the pins plugs into the female receptacle containing the sockets. They are especially resistant to environmental interference and accidental decoupling through the use of screw, bayonet, twist-lock and push-pull mating styles and can be sealed to IP67 or higher.

When the male plug and female receptacle are pushed together and make contact electrical current flows through the electrical contacts that are made from high-conductivity, oxidation-resistant materials like brass and steel. These can be bare or plated in gold and/or silver to offer better conductivity for lower voltages and currents. They are usually attached to each wire strand within the cable using solder or screw fittings or by using a crimping tool, which employs a solderless crimp mechanism. Each contact is passed through the circular connector housing and insert before the connector backshell is closed. In the case of a crimp fitting individual contacts can be replaced without requiring the entire connector having to be replaced.

Circular connectors commonly use backshells, which provide physical and electromagnetic protection as well as also providing a method for locking the connector into a receptacle which provides stress relief for the attached cable. In some cases this backshell provides a hermetic seal or some degree of ingress protection. As well as protecting the multi pin circular connector and cable link from physical stress like strain, shock or vibration, backshells can also stop any electromagnetic interference that can occur when lightning strikes an aircraft or wind turbine tower. Backshells are also known as endbells, strain-relief clamps or cable clamps.